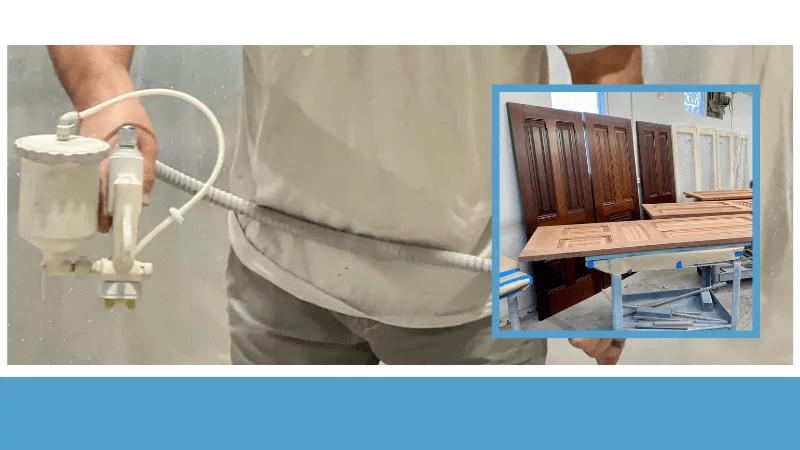

Spraying polyurethane with an HVLP spray gun is widely considered one of the most effective methods for achieving a flawless and even finish. However, this technique does present its fair share of challenges. In this comprehensive article, we will delve into the fundamentals of spraying polyurethane, covering everything from choosing the right nozzle size to properly thinning polyurethane for optimal spraying results. Whether you’re a beginner or an experienced user, this article has got you covered from A to Z.

See Top sprayers for polyurethane

Gun setup for spraying polyurethane

| Gun Type | Recommended Nozzle Size |

|---|---|

| Gravity Feed | 1.5mm – 1.9mm |

| Pressure Cup | 1.0mm – 1.3mm |

| Siphon Cup | 1.9mm – 2.5mm |

Proper Handling of the Spray Gun

Properly handling the spray gun is essential for achieving a smooth and even finish. This is not only true for spraying polyurethanes but true for all finishes. Follow these guidelines to ensure the effective and efficient use of the spray gun:

Holding the Spray Gun:

Hold the spray gun with a comfortable and firm grip. Keep your wrist straight and maintain a steady hand throughout the spraying process. This helps to maintain control and stability.

Distance from the Surface:

Maintaining an optimal and consistent distance between the spray gun and the surface being sprayed is crucial for achieving a flawless finish. While the recommended distance typically falls within the range of 6 to 8 inches (15 to 20 cm), it’s important to consider additional factors such as the make of the spray gun, the type of finish being applied, and the power of the compressor. By adhering to these guidelines, you ensure that the material is evenly distributed across the surface, resulting in a consistent and professional outcome.

Overlapping Strokes:

Spray in overlapping strokes to ensure consistent coverage. Start each stroke slightly before the previous one ends, and maintain a consistent speed and pattern. This technique helps to avoid uneven application and reduces the risk of visible lines, missed spots, or streaks.

Adjusting the Fan Pattern:

Most HVLP spray guns allow you to adjust the fan pattern according to your needs. For larger areas, a wider fan pattern is preferable, while narrower patterns are suitable for smaller, more intricate areas. Adjust the fan pattern by turning the control knob on the spray gun.

Controlling the Fluid Flow:

The fluid flow or material volume can be adjusted using the control knob or dial on the spray gun. Start with a lower flow rate and gradually increase it until you achieve the desired coverage. Avoid excessive flow rates, as they can lead to drips or pooling.

Practice Proper Trigger Control:

Maintain smooth and consistent trigger control throughout the spraying process. Avoid abrupt or jerky movements that can result in uneven application. Practice your trigger control technique before starting the actual spraying to ensure precision and accuracy.

Test Sprays and Adjustments:

Before spraying the actual project, perform test sprays on a scrap piece or an inconspicuous area. This allows you to adjust the spray gun’s settings, such as fluid flow and fan pattern, to achieve the desired result.

Once you feel comfortable and confident with handling the spray gun, you’re ready to move on to the actual project and apply polyurethane. Follow this step-by-step guide to ensure a successful application:

How to spray polyurethane with an HVLP spray gun

Before we get to spraying you need to prepare your work area. To prepare the work area for spraying polyurethane, it is important to create a clean and well-ventilated space. This involves clearing the area of unnecessary items, thoroughly cleaning the surfaces to be sprayed, eliminating potential sources of contamination, using protective coverings, and ensuring proper lighting. Taking these steps sets the stage for a successful polyurethane application in the next steps.

Section 1: Sealing the Wood with Dewaxed Shellac

Before spraying polyurethane, particularly if it is water-based, it is advisable to seal the wood with dewaxed shellac. Dewaxed shellac acts as an excellent sealer that does not raise the grain much. Additionally, it dries quickly and is easy to sand.

Section 2: Sanding the Sealer Coat

To achieve a smooth finish, it is important to sand the sealer coat. Follow these steps:

- Use 600-grit sandpaper to sand the fully dried sealer coat.

- Allow the sealer coat to dry overnight before attempting sanding.

Section 3: Ensuring a Clean Gun

Inspect and clean the spray gun thoroughly to avoid any potential issues. Clean the gun and remove any remaining finish residue from the previous use. This step ensures that there is no contamination, reducing the chances of any problems during the spraying process.

Section 4: Applying the Finish

When applying the polyurethane finish, it is best to start with the least visible areas, such as the underside of your project. This approach allows for adjustments to the fan width and helps in achieving a consistent and smooth flow of the polyurethane.

Section 5: Dealing with Vertical Drips

Spraying vertical surfaces can be challenging, as it may result in vertical drips, particularly with water-based finishes that tend to be lighter. Be vigilant and take the necessary precautions to avoid vertical drips, as they can affect the overall finish quality.

Section 6: Applying Heavy Coats for High-Traffic Areas

In areas that experience high traffic or heavy use, applying a heavy coat of polyurethane is beneficial. This provides a tougher protective surface, enhancing durability and longevity.

Spraying polyurethane with an HVLP- Summary

Spraying polyurethane with an HVLP spray gun offers a reliable method for achieving an even and professional finish. While it presents its challenges, proper handling of the spray gun and following best practices can lead to excellent results. Remember to be cautious of vertical drips and consider applying heavy coats in high-traffic areas for enhanced protection. With this comprehensive guide, both beginners and experienced users can confidently achieve outstanding results when spraying polyurethane with an HVLP spray gun.