Wood staining can be a challenging and confusing process for many people, often due to the lack of reliable information available on the subject. The complexity of this wood-finishing technique may be attributed to the common misuse of the term “stain” as a synonym for “finish”. This can lead to misconceptions about staining, including whether it is a protective finish, akin to polyurethane.

Questions such as, “Is stain as effective as polyurethane?” and “Do we need to polyurethane after staining it?” Prompt a need to dispel these doubts and gain a better understanding of wood staining.

Related article: Sealing wood before staining

Stains for wood and how they work

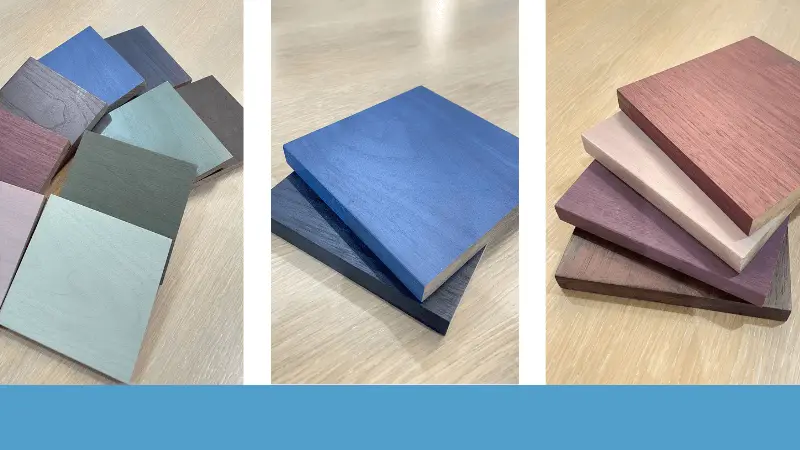

Stains are absorbed into the wood fibers and penetrate the wood with their color, enhancing its natural beauty. Unlike paint, stains do not cover the wood grains, but instead, they add a new shade or tint of color, accentuating the wood’s natural grain pattern.

This unique ability to change the wood’s color without hiding its natural beauty is one of the primary reasons why many people find wood staining so attractive. By using stain, plain and inexpensive woods can be transformed to look like exotic woods with beautiful color variations.

More on Poly: Can you mix different brands of polyurethane? Find out

Why do you need to seal the wood after staining

However, it’s important to note that stains alone do not provide protection for wood against moisture, heat, or checking. For this reason, it’s essential to use a protective finish, such as polyurethane, after staining to safeguard the wood’s beauty and integrity.

Brushing polyurethane over stain

When applying polyurethane over stain, there are generally no major concerns to be aware of, but it’s important to follow some guidelines to ensure the best results. Firstly, make sure that the stain is completely dry before applying the polyurethane. This ensures that the polyurethane will adhere properly to the stain and create a smooth, even finish.

It’s also important to choose the right type of polyurethane based on the type of stain you’ve used. If you’ve used an oil-based stain, use water-based polyurethane to avoid splotches. On the other hand, if you’ve used a water-based stain, switch to an oil-based polyurethane. The logic behind this is that water-based polyurethane is made of water, which can cause parts of the water-based stain to lighten once it comes into contact, leading to an uneven and unattractive finish.

Special stains that don’t need a topcoat

It’s important to note that not all stains are created equal. In fact, some stains come with an inbuilt varnish or polyurethane, which not only stains the wood but also leaves a protective topcoat on the wood surface. These types of stains are available in gel form or come pre-mixed with a liquid finish, often polyurethane. When using such a stain, there is no need to apply a separate polyurethane coat for protection. One popular example of such a stain is the Polyshades product line by Minwax, which offers both color and protection in one easy step.

Similarly, some deck stains are also formulated with polyurethane, providing a protective barrier against the elements. This means that these stains do not require an additional protective coating, as the polyurethane within the stain already offers sufficient protection. It’s important to read product labels carefully and choose the right type of stain for your project, depending on the level of protection and finish desired.

Can you mix polyurethane with stain?

If you prefer to use both stain and polyurethane together, you can mix them in a single application instead of applying the stain and coating it with polyurethane afterward. However, it’s essential to ensure that the polyurethane and stain are compatible to avoid any issues.

It’s also important to mix and test the stain and polyurethane on a scrap piece of wood before applying it to your project to achieve the desired color and finish. This process can help prevent any unwanted surprises and ensure that the final product meets your expectations. By testing the mixture first, you can adjust the ratio of stain to polyurethane to achieve the desired color and finish, ensuring a successful project.

Related: Water based polyurethane over shellac

Summary: Do you need polyurethane after staining

- Staining wood enhances its natural beauty and adds color without hiding its natural grain pattern.

- Stains alone do not provide protection against moisture, heat, or checking. A protective finish, such as polyurethane, is necessary after staining to safeguard the wood’s beauty and integrity.

- When applying polyurethane over stain, it is essential to ensure that the stain is completely dry before applying the polyurethane to achieve a smooth, even finish.

- Choosing the right type of polyurethane based on the type of stain used is crucial. If an oil-based stain is used, use water-based polyurethane to avoid splotches. If a water-based stain is used, switch to oil-based polyurethane.

- Some stains come with an inbuilt varnish or polyurethane, which not only stains the wood but also leaves a protective topcoat on the wood surface, making a separate polyurethane coat unnecessary.

- Mixing polyurethane with stain is possible, but it is crucial to ensure that the polyurethane and stain are compatible and to mix and test them on a scrap piece of wood before applying them to the project.