Get ready for a comprehensive exploration of varnish finishes. Known for its exceptional protection and durability, varnish creates a robust barrier against water, heat, wear, solvents, acids, and alkalis. Although it’s cost-effective and builds quickly, varnish can be the most difficult of all finishes to apply with good results. Stay tuned as we delve into the intricacies of varnish finishes and uncover more about their nature.

What is varnish wood finish?

Varnish is a protective coating created by combining curing or modified semi-curing oil with resin. Traditionally, linseed oil was used, but tung oil and other oils were introduced later. Resins were derived from fossilized sap, primarily imported copals like kauri, congo, and manila, as well as amber. Today, innovative chemists have unlocked the potential of soybean and safflower oils, yielding affordable varnishes with reduced yellowing tendencies. Natural resins are rarely used in varnish production today. If that sounded a little complex don’t worry the upcoming sections will shed some light.

How varnish works

The Mix of Oil and Resin

Whichever oils and resins are used in making varnish, the ratio of oil to resin plays a vital role. This ratio determines the characteristics of the resulting cured-varnish film. Let’s explore the intriguing effects of different oil-to-resin ratios.

Long-Oil Varnish: Flexibility for the Outdoors

Varnish with a high percentage of oil is referred to as long-oil varnish. You might have come across terms like “spar” or “marine” varnish, designed for outdoor use. Long-oil varnishes offer more flexibility to accommodate the natural movements of wood. They are particularly suitable for environments where wood movement is a concern. These varnishes create a cured film that is softer and more flexible. See Best Varnish for Pine floor: Guide and product review

Short-Oil or Medium-Oil Varnish: Harder Finish for Indoors

In contrast, varnishes made with a low percentage of oil are known as short-oil or medium-oil varnishes. These varnishes are intended for indoor use, where extreme wood movement is not a problem. The resulting cured-varnish film is harder and more brittle, ideal for achieving a desired durable finish indoors.

Unveiling the Resin and Oil Secrets

The choice of resins and oils in varnish production also holds significance, contributing to the unique properties of the final product.

- Phenolic Resin: Tough and Yellowing Phenolic resin, notorious for its significant yellowing effect, brings both toughness and flexibility to varnishes. It has a historical association with vintage radio cases and rubbing varnishes for exquisite tabletops and pianos.

- Alkyd Resin: Common and Versatile Alkyd resin, more cost-effective and less prone to yellowing, stands as the most widely used resin in varnish production. Its adequate toughness and versatility make it suitable for various applications.

- Polyurethane Resin: The Tough Protector Polyurethane resin, the mighty champion among varnish resins, often joins forces with alkyd to create one-part polyurethane finishes. These finishes offer exceptional durability. However, they may have a slightly cloudy appearance when applied thick. It’s important to note that polyurethane varnish requires proper surface preparation before recoating and doesn’t fare well under prolonged exposure to sunlight.

Characteristics of Varnish: Unveiling Its True Nature

Varnish, beyond its mesmerizing color variations, possesses a set of distinct characteristics, all stemming from its reactive curing process. Let’s explore these fascinating traits that define varnish’s unique nature:

1. Excellent Resistance to Water and Water-Vapor Exchange

Thanks to its crosslinked molecular network, varnish forms a formidable barrier against water and water-vapor penetration. The reduced size of the spaces within the molecular structure restricts the passage of moisture, providing exceptional resistance.

2. Exceptional Resistance to Heat, Wear, Solvents, Acids, and Alkalis

The cured film of varnish boasts exceptional durability due to the cross-linking of resin molecules. Breaking apart these tightly bonded molecules requires high heat, sharp force, or potent solvents and chemicals. Varnish stands strong against everyday wear and tear, solvents, acids, alkalis, and other challenges.

3. Long Curing Time: A Double-Edged Sword

Varnish exhibits a slow oxidation process during curing, offering ample time for brush application without becoming tacky or dragging. However, this extended curing time also presents a challenge in terms of dust accumulation. Dust settling on the varnish’s wet or tacky surface detracts from the final result, demanding careful attention to maintain a flawless finish.

4. Repair and Stripping: A Challenging Task

Varnish’s remarkable solvent, heat, and chemical resistance also present a downside: repairing and stripping become more challenging endeavors. The strong molecular bonds make it difficult to reverse the curing process, requiring careful consideration and specialized techniques for restoration or removal.

5. Difficulty in Achieving an Even Sheen

The flip side of varnish’s remarkable wear resistance is the challenge of achieving an even sheen. The strong molecular structure that protects against wear makes it more difficult to achieve a perfectly uniform surface appearance. Skillful rubbing techniques and meticulous attention to detail are essential for attaining the desired sheen.

6. Skinning Over in the Can: A Natural Reaction

As varnish cures through oxygen absorption, any air remaining in a can of varnish initiates the curing process. Over time, this can lead to skinning, where a thin layer forms on the surface. To prevent this, it is advisable to transfer the varnish to a smaller container, eliminating excess air that could cause skinning. Additionally, products like “Bloxygen” can replace the air with inert gas, preserving the varnish’s integrity.

Pros & Cons of varnish finishes

Pros

- ■ Excellent heat, wear, solvent, acid, and alkali resistance

- ■ Excellent water and water-vapor resistance

- ■ Brushes easily with long open time

Cons

- ■ Very slow curing, resulting in dust problems and runs

- ■ Yellows over time

Tips for Applying Varnish

When it comes to applying varnish, there are some key considerations to ensure a successful outcome.

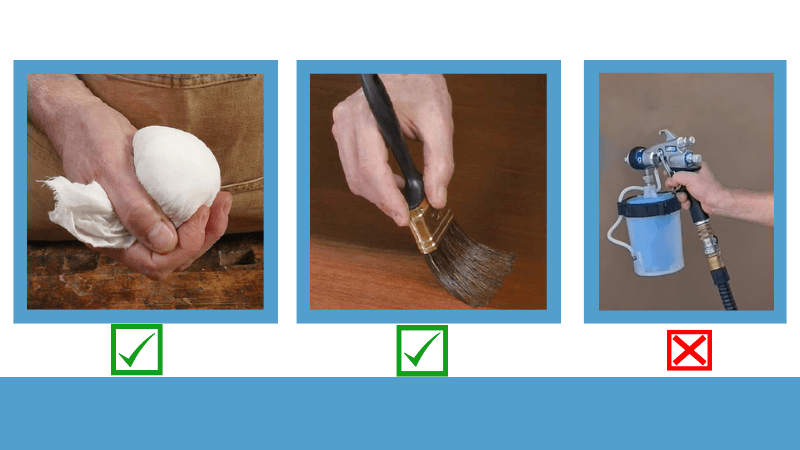

1. Embrace the Brush, Leave the Sprayer Behind

Varnish is a delight to brush and a challenge to spray. The ample time available for brush application allows for even spreading on the wood surface. Spraying, on the other hand, can be troublesome, as uncured varnish particles float in the air, settling on everything and making your skin sticky. While some brave souls venture into spraying varnish, brushing remains the preferred method for most enthusiasts.

2. Building Thickness with Efficiency

Varnish possesses a high solids content, allowing you to achieve a significant film thickness with just a few coats. Typically, one sealer coat followed by two coats of full-strength varnish is sufficient. The high-solids composition of varnish ensures efficient coverage and durable protection for your woodwork.

3. Weather’s Influence on Curing

The weather has a direct impact on varnish curing time. Cold and damp conditions significantly slow down the curing process, and temperatures below 60 degrees Fahrenheit may extend the curing period to several days. Conversely, hot weather accelerates the curing process, with thinner evaporating faster and varnish reacting more rapidly with oxygen. However, extremely high temperatures, such as 90 degrees or higher, can pose challenges during brush application, with brush marks struggling to level out and air bubbles having limited time to pop before the varnish cures. Refer to the “Common Problems Using wipe-on Varnish”

4. Temperature Adjustments and Thinning

To counter the effects of cold or damp weather, consider raising the temperature in your working area to expedite the curing process. Conversely, on hot days, you can slow down the curing by adding 5 to 10 percent mineral spirits (paint thinner) to the varnish. This not only eases spreading and promotes smoother flow but also allows air bubbles more time to escape the finish. Many experienced finishers opt to thin each coat slightly, although this may require applying additional coats to achieve the desired build.

The Concept of Wiping Varnish

In the realm of wood finishing, the term “wiping varnish” emerged in 1990 (by Bob Flexner in an article in Woodwork magazine), revolutionizing the approach to a popular finish. It refers to the practice of thinning varnish with mineral spirits to create a user-friendly finish. Interestingly, there are no specific products labeled as “wiping varnish” available in the market. Instead, alternative names are used to describe similar finishes, such as “Tung Oil,” “Tung Oil Finish,” “Tung Oil Varnish,” “Salad Bowl Finish,” or proprietary names like Waterlox, Seal-a-Cell, ProFin, or Val-Oil.

The Labeling Conundrum

The purpose behind the term “wiping varnish” was to distinguish thinned varnish from the misleading and uninformative labeling prevalent in the industry. By diluting varnish with mineral spirits, it becomes effortless to apply the finish by wiping it onto the wood surface. However, the absence of a specific label for wiping varnish has led to a range of alternative product names that offer the same characteristics.

Understanding the Varied Labels

It is important to note that despite the different labels, all these finishes are varnishes (and sometimes polyurethane varnishes). When applied with sufficient coats to achieve the desired build on the wood, they provide excellent protection and durability. However, the challenge lies in the labeling itself, which compromises effective communication and often leads to finishing failures.

For instance, when someone mentions the use of tung oil on their project, it is unclear whether they used genuine tung oil, thinned varnish, or an oil/varnish blend. These are distinct finishes with varying characteristics. Such labeling ambiguity poses challenges and creates confusion among finishers, hindering their ability to make informed choices.

Embracing Clarity for Successful Finishing

In essence, the beauty of wiping varnish lies not only in its application ease and versatility but also in understanding the subtle differences between the various labels. By demystifying the labeling confusion and fostering a clearer understanding, finishers can confidently navigate the realm of finishes, ensuring successful and gratifying outcomes for their woodworking projects.

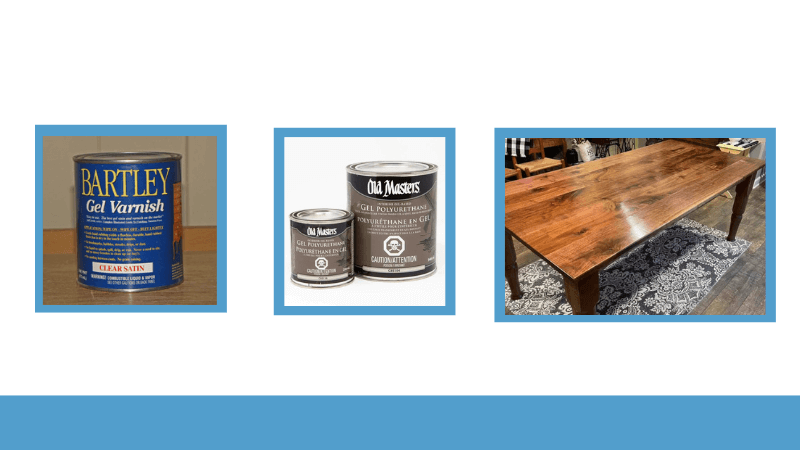

Gel Varnish

Gel varnish provides a distinct approach to finishes by offering a thickened wiping varnish without the pigment typically found in gel stains. It is designed to be applied by wiping it onto the wood surface and subsequently wiping off the excess. Unlike wiping varnishes, gel varnishes often result in a satin sheen, setting them apart from gloss finishes commonly achieved with wiping varnishes.

Easy Application

Applying gel varnish is a straightforward process that requires a cloth for even distribution. Due to its relatively rapid drying time, it is important to promptly wipe off any excess after application. In the event that the excess begins to set up, it can be removed quickly using naphtha or mineral spirits. Sanding between coats can be done to eliminate dust or imperfections. Typically, three or four coats are sufficient to achieve the desired appearance.

The Future of Varnish: Adapting to Changing Regulations

The Changing Landscape

With the implementation of solvent content restrictions in various regions, the varnish industry is undergoing transformations to comply with these regulations. Manufacturers are exploring different approaches, including the production of thicker varnishes, the use of resins with smaller molecular weights, and the substitution of non-evaporating oils for thinners.

Thicker Varnishes

Thicker varnishes present unique challenges during application, such as more noticeable brush marks. Manufacturers may discourage thinning varnish to meet VOC (Volatile Organic Compounds) laws, but thinning varnish is a viable option that renders it non-compliant with these regulations.

Smaller Molecular Weight Resins

The use of resins with smaller molecular weights may result in slower curing times and potentially reduced protective and durable qualities of the varnish. Manufacturers can partially compensate for this by adjusting the mix of driers, although this is not uniformly implemented. Identifying varnishes with these characteristics can be challenging without explicit labeling or noticeable performance differences.

Non-Evaporating Oils

The addition of non-evaporating oils to varnish extends the curing process and yields a less rigid finish. Similar to other cases, manufacturers may not explicitly indicate the presence of these oils on the label, requiring careful observation to identify any discrepancies.

Navigating the Future

Choosing varnish or polyurethane products requires increased discernment in response to changing regulations. If the varnish being used fails to dry or harden correctly, and external factors such as temperature or wood oils are not to blame, it may be worth exploring alternative brands. As we move forward, collaboration between governments and the industry will ideally lead to the development of environmentally friendly finishes that meet both regulatory requirements and quality standards.