Wood finishing tools an overview is crafted specifically with beginners in mind. However, don’t be mistaken—this guide has something valuable for enthusiasts of all skill levels. While we start by exploring the fundamentals, we quickly dive into the depths of what can be accomplished with even the simplest of tools. Prepare to have your perceptions challenged and your creative boundaries expanded.

We understand that as a beginner, you may be tempted to overlook the humble brush, dismissing it as a basic tool. But hold on tight, because we’re about to reveal the astonishing potential that lies within. From delicate strokes that create intricate patterns to bold sweeps that bring out the natural beauty of wood, you’ll be amazed by the versatility and transformative power of this seemingly ordinary tool. But that’s not all, spray guns, rugs, rollers, and more in a minute.

Types of Wood Finishing Tools: Rags, Brushes, and Spray Guns

When it comes to wood finishing, the tools you choose can make a significant difference in the final outcome. In this section, we’ll explore the three primary types of wood finishing tools: rags, brushes, and spray guns. Each tool has its unique characteristics, advantages, and considerations. Let’s dive into the details.

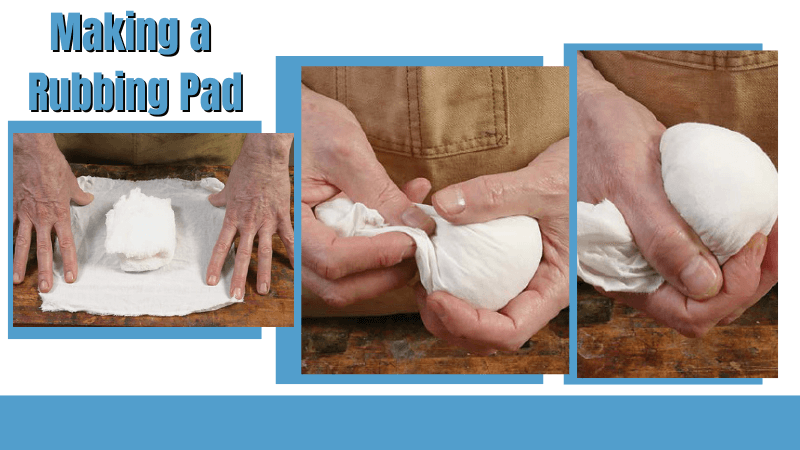

Rags: The Timeless Choice

Rags have been a long-standing favorite among woodworkers for applying stains, finishes, and paints. They offer simplicity and affordability, making them a popular option for beginners and those on a tight budget. Old cotton clothing can be repurposed into rags, making them a cost-effective choice.

Benefits of Rags:

- Cost-effective: Rags can be acquired at minimal or no cost, especially when recycling old garments.

- Versatile: Rags allow for smooth, controlled application and are great for wiping off excess product.

- Ideal for smaller projects: Rags provide excellent precision for intricate areas and smaller surfaces.

Considerations:

- Potential for uneven application: Rags may leave deep ridges in the film if not applied carefully.

- Limited coverage: Rags are suitable for smaller areas and may require additional effort for larger projects.

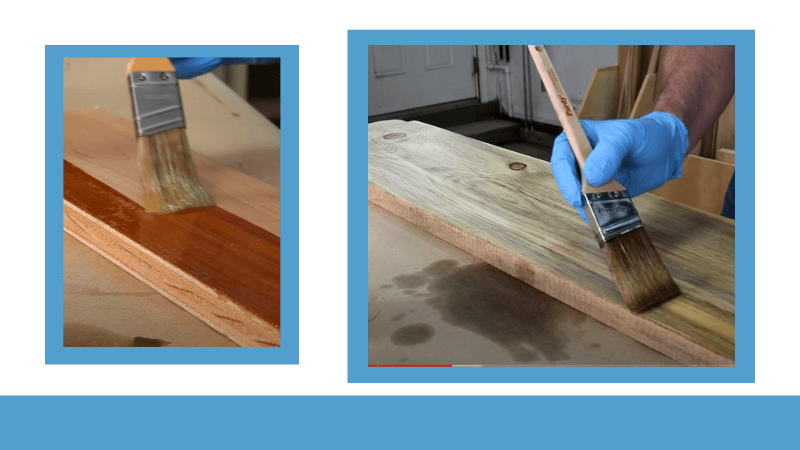

Brushes: Precision and Control

Brushes are a classic choice for wood finishing, offering control, versatility, and the ability to create textured effects. With a wide range of brush types and sizes available, you can find the perfect brush for your specific application needs. (See top floor finishing brushes).

Benefits of Brushes:

- Precision application: Brushes allow for precise control and are ideal for reaching tight corners and intricate details.

- Textured finishes: Brushes can create unique textures, including brush strokes, which add character to your woodwork.

- Wide variety: Different brush bristles, such as natural or synthetic, provide options for specific coatings and finishes.

Considerations:

- Brush marks: Even with sponge brushes, ridges can be left at the edges, requiring extra care during application.

- Brush cleaning: Brushes require thorough cleaning after each use to maintain their performance and longevity.

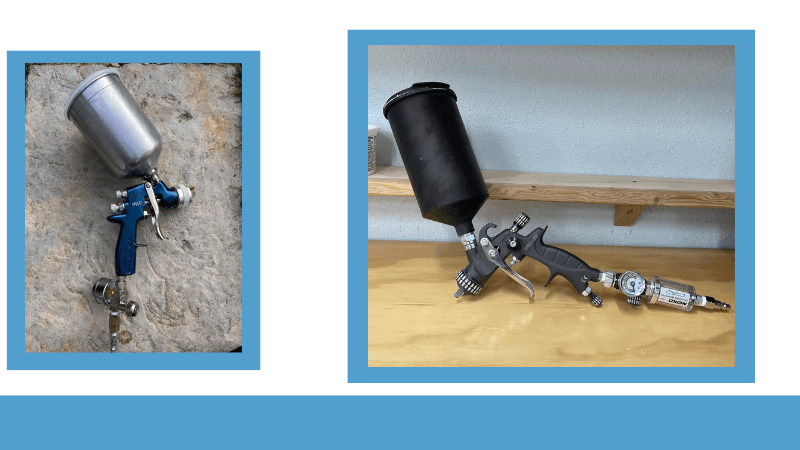

Spray Guns: Efficiency and Professional Results

Spray guns have revolutionized the wood finishing industry, offering speed, efficiency, and a flawless finish. While they require a higher upfront investment, spray guns provide an exceptional level of control and are favored by professionals for large-scale projects. (See our top polyurethane sprayers)

Benefits of Spray Guns:

- Efficient application: Spray guns cover larger areas quickly, making them ideal for extensive projects.

- Smooth, level finish: Spray guns produce a consistent and level surface, minimizing brush marks and ridges.

- Versatility: Spray guns can be used with a variety of coatings, including stains, finishes, and paints.

Considerations:

- Cost: Spray guns tend to be more expensive than rags or brushes, requiring an initial investment.

- Overspray management: Proper ventilation and overspray control are necessary to prevent unwanted coating on surrounding objects.

- Maintenance: Spray guns require thorough cleaning and maintenance to ensure optimal performance.

| Rags | Brushes | Spray Guns | |

|---|---|---|---|

| Cost | Very little to no cost | Inexpensive | Higher initial investment |

| Speed | Slower application on larger areas | Moderate application speed | Faster application on larger areas |

| Film Leveling | Tends to leave deep ridges | May leave brush marks or ridges | Produces a smooth, level surface |

| Weather | Suitable for indoor and outdoor use | Suitable for indoor use; overspray management | Requires proper ventilation and overspray control |

| Versatility | Limited to smaller projects | Versatile for various applications | Versatile for various coatings and projects |

| Control | Limited precision and control | Good precision for intricate areas | Excellent control and precision |

| Textured Finish | Not suitable for textured effects | Can create textured effects (e.g., brush strokes) | Not suitable for textured effects |

| Maintenance | N/A | Regular cleaning required | Regular cleaning and maintenance required |

Choosing a Brush

When it comes to wood finishing, a brush stands out as one of the most versatile and approachable tools in your arsenal. this is why it justifies dedicating this section to choosing a good quality brush. A good brush not only enhances your control but also provides durability for long-lasting performance. In this section, we’ll check the various types of brushes available and highlight the key qualities to consider when making your selection.

Types of Brushes

- Natural Bristle Brushes: Natural bristle brushes are made from animal hair and are favored for their performance with solvent-based finishes. The finest natural-bristle brushes are crafted from Chinese hog hair, offering excellent stiffness and control. However, natural-bristle brushes are not suitable for water-based stains or finishes, as the hair becomes uncontrollable when wet.

- Synthetic Bristle Brushes: Synthetic bristle brushes, made from materials like polyester or nylon, are ideal for water-based stains and finishes. Polyester adds stiffness to the brush, while nylon provides softness and flexibility. Synthetic-bristle brushes offer versatility and can be used with both solvent-based and water-based coatings.

- Foam Brushes: Foam brushes are a popular choice for minimal brush marking and easy cleanup. They are affordable and often disposable, making them convenient for one-time use. However, foam brushes tend to leave distinct ridges at the edges of each brushstroke due to the deposition of more finish in those areas. Denser foam brushes generally perform better than less dense ones.

- Paint Pads: Paint pads consist of thousands of short filaments attached to a foam backing and are commonly mounted in flat plastic or metal holders. They function similarly to foam brushes but are primarily suitable for flat surfaces. Paint pads are popular among floor finishers due to their ability to hold a substantial amount of finish. As with foam brushes, paint pads should not be used with lacquer and should be tested with shellac before use.

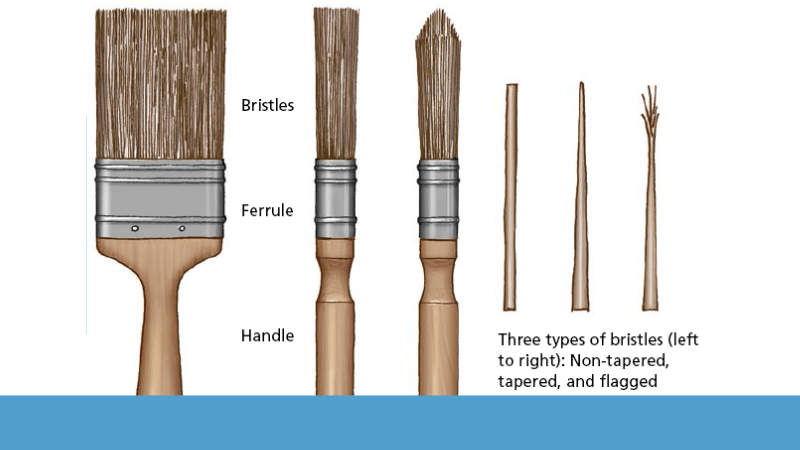

Key Qualities of a Good Brush

When selecting a brush for your wood finishing projects, consider the following qualities:

- Chisel Shape: Look for brushes with bristles arranged to form a chisel shape, where the center bristles are longer than the bristles on each flat side. This design enables a smoother and more even application of the finish.

- Tapered Bristles: Opt for brushes with tapered bristles, as the thickness near the ferrule provides stiffness while the thinness at the tip offers flexibility and softness. Softer-tipped bristles tend to create fewer pronounced brush marks.

- Flagged Bristles: Flagged bristles, which are split into several fibers at the tips, increase the number of bristle fibers that come into contact with the surface. This allows for better finish coverage and smoother application.

- Minimal Bristle Shedding: Choose brushes that have very few bristles falling out, as excessive shedding can lead to an uneven finish.

Remember, while the brush quality is important, the choice of finish also plays a significant role in the final result. Some brands of finish may level out better regardless of the brush used.

More finishing tool resources

Wood finishing tools summary

In this comprehensive guide on wood finishing tools, we have aimed to provide valuable insights and guidance to beginners and woodworking enthusiasts alike. Our goal is to challenge your perceptions, expand your creative boundaries, and empower you to achieve stunning results in your woodworking endeavors. Now, let’s summarize the key points covered in this article.

- Types of Wood Finishing Tools: We explored three primary types of wood finishing tools: rags, brushes, and spray guns. Each tool has its unique characteristics, advantages, and considerations. Rags offer simplicity and affordability, brushes provide precision and control, and spray guns offer efficiency and professional results.

- Rags: Rags are a timeless choice, favored for their cost-effectiveness and versatility. They are ideal for smaller projects, provide a smooth application, and can be repurposed from old clothing. However, there is a potential for uneven application and limited coverage with rags.

- Brushes: Brushes are a classic option that allows for precision and control. They come in various types and sizes, offering textured finishes and versatility. Natural bristle brushes excel with solvent-based finishes, while synthetic bristle brushes are suitable for water-based stains and finishes. Foam brushes and paint pads are alternative options with their own advantages.

- Spray Guns: Spray guns have revolutionized the wood finishing industry, providing efficiency, speed, and a flawless finish. While they require a higher upfront investment, spray guns are favored by professionals for large-scale projects, offering excellent control and versatility.

- Key Qualities of a Good Brush: When choosing a brush, consider the chisel shape, tapered bristles, flagged bristles, and minimal bristle shedding. These qualities ensure smoother and more even application, fewer brush marks, and better finish coverage.

By understanding the characteristics and considerations of each wood finishing tool, you can make informed choices based on your project requirements, budget, and desired outcome. Remember, the quality of the finish used also plays a significant role in the final result. Exploring different tools and techniques will help you discover your preferred method and unleash your creative potential.