When it comes to finishing your woodworking projects, choosing the right finish is crucial for achieving both aesthetic appeal and long-lasting durability. With numerous options available, it can be overwhelming to make the right choice. In this article, we will explore different types of finishes, their characteristics, and factors to consider when choosing the ideal finish for your woodworking projects.

Understanding Different Types of Wood Finishes

Wood finishes play a vital role in enhancing the beauty and durability of woodworking projects. There are various types of wood finishes available, each with its own characteristics and benefits. Understanding these finishes is crucial for selecting the right one for your project. Here are the main types of wood finishes to consider:

A. Penetrating Finishes

Penetrating finishes, such as oil finishes, work by soaking into the wood fibers, enhancing the natural beauty of the wood while providing protection. Tung oil and linseed oil are popular examples of penetrating finishes. These finishes offer a more matte appearance, maintaining the wood’s natural look.

B. Surface Finishes

Surface finishes create a protective layer on top of the wood, offering excellent durability and moisture resistance. There are several types of surface finishes to choose from:

- Varnishes: Varnishes provide a glossy and refined appearance. They offer excellent protection against moisture and wear, making them ideal for high-traffic areas like tabletops and furniture.

- Lacquers: Lacquers are known for their high clarity, allowing the natural depth of the wood to shine through. They provide a warm and amber-toned finish and offer moderate protection.

- Shellac: Shellac is a versatile finish that provides a warm and natural appearance. It offers good protection against water vapor exchange, making it suitable for various woodworking projects.

- Polyurethane: Polyurethane finishes offer a glossy and durable surface. They provide excellent protection against moisture, scratches, and chemicals. However, they can be more challenging to apply and reverse.

Factors to Consider When Choosing a Finish

I. Appearance

Achieving the desired aesthetic appeal is an essential factor when selecting a finish for your woodworking projects. Consider the following sub-factors:

- Film Build:

- The level of sheen and smoothness desired for the project should be taken into account.

- Film finishes, such as varnishes, offer a glossy appearance, while oil finishes provide a more natural, matte look.

- Clarity:

- Some finishes, like dewaxed shellac and lacquer, provide high clarity, allowing the natural depth of the wood to show through.

- Color:

- Different finishes can enhance or alter the wood’s color. Consider whether you want to enhance warmth or coolness or preserve the wood’s natural color.

II. Protection

Protecting the wood from various elements and potential damage is crucial for ensuring the longevity of your woodworking projects. Consider the following sub-factors:

- Water Resistance:

- For tabletops and items exposed to moisture, choose finishes with excellent water resistance, such as varnishes or two-part epoxy.

- Vapor Resistance:

- Consider the finish’s ability to resist water vapor exchange, which can affect joint stability and veneer adhesion.

III. Durability

The durability of the finish plays a significant role in determining how well it can withstand daily use and potential wear and tear. Consider the following sub-factors:

- Scratch and Wear Resistance:

- Evaluate the finish’s ability to resist scratches and general wear. Varnishes and polyurethane finishes offer excellent durability in this regard.

- Chemical Resistance:

- Consider the finish’s resistance to solvents, acids, alkalis, and household chemicals. This is especially important for projects that may come into contact with such substances.

IV. Application Ease

The ease of applying the finish is an important consideration, especially for those with limited experience in woodworking. Consider the following sub-factors:

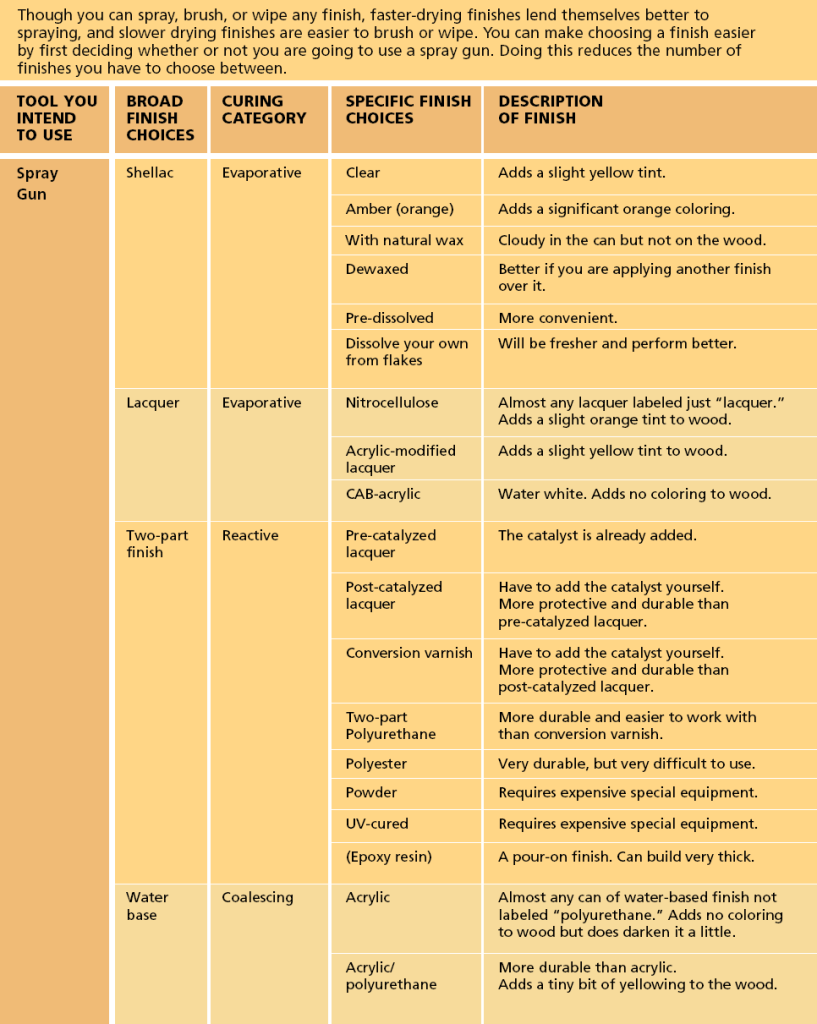

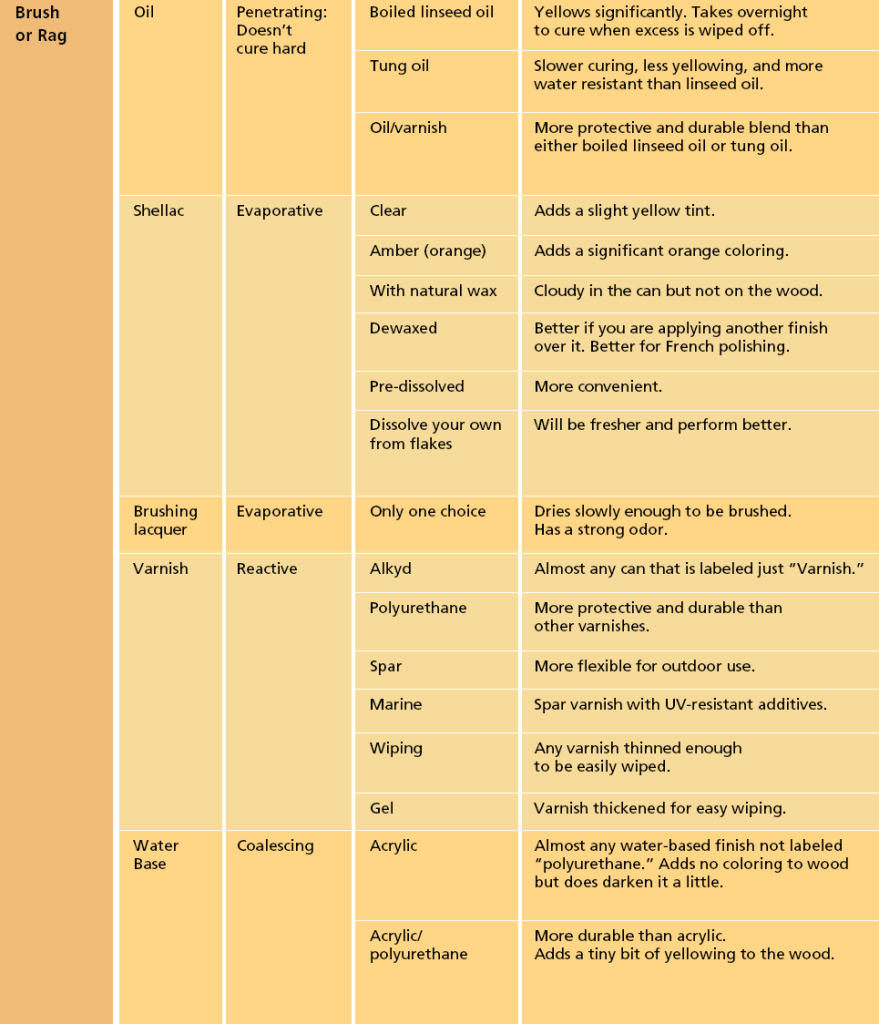

- Spray or Brush:

- Determine whether you have access to spray equipment. Spraying offers a more even application and is suitable for most finishes.

- Drying Time:

- Finishes with faster drying times are generally easier to apply, especially for brush applications.

V. Safety

Safety should always be a top priority when working with finishes, as some may pose health risks or have flammability concerns. Consider the following sub-factors:

- Flammability:

- Take precautions when working with flammable finishes and avoid open flames or sparks in the workspace.

- Toxicity:

- Consider the level of fumes and toxicity associated with the finish. Proper ventilation is crucial to minimize health risks.

VI. Reversibility

Consider the ease of repair, touch-up, and potential changes in the future when choosing a finish. Consider the following sub-factors:

- Repair and Touch-Up:

- Some finishes, like shellac, are easier to repair and touch up. Consider the ease of maintenance and potential changes you may need to make in the future.

- Removal:

- Crosslinking finishes, although more durable, are challenging to remove. Shellac and lacquer are more easily reversible.

By considering these factors, you can make an informed decision when choosing a finish for your woodworking projects. Remember to evaluate each factor based on the specific requirements of your project to achieve the best results in terms of appearance, protection, durability, application ease, safety, and reversibility.

Comparison Chart: Key Characteristics of Wood Finishes

The following chart summarizes the key characteristics of popular wood finishes:

| Finish | Appearance | Protection | Durability | Ease of Application | Safety | Reversibility |

|---|---|---|---|---|---|---|

| Oil Finishes | Natural, matte | Moderate | Moderate | Easy | Low | Moderate |

| Varnishes | Glossy, refined | Excellent | High | Moderate | Moderate | Difficult |

| Shellac | Warm, amber | Good (water vapor) | Moderate | Easy | Low | Moderate |

| Lacquer | High clarity | Fair | Moderate | Moderate | Moderate | Difficult |

| Polyurethane | Glossy, durable | Excellent | High | Moderate | Moderate | Difficult |

Guide to choosing a finish

Conclusion: Choosing the Right Finish

In conclusion, now that you have considered the essential factors for choosing the right finish for your woodworking project, it’s important to delve deeper into the specific type of finish you have selected. Within each category, such as oil, varnish, or lacquer, there are variations that offer unique characteristics and benefits. Take a closer look at the Finish category dedicated to your chosen finish type (scroll to the bottom to see Links), where you will find valuable information and insights.

For instance, if you have decided on using an oil finish, you still have the opportunity to choose between boiled linseed oil, tung oil, or an oil/varnish blend. Similarly, if varnish is your preferred option, you can explore the differences between alkyd varnish, polyurethane varnish, and marine varnish. If lacquer is your choice, you can consider nitrocellulose lacquer, acrylic-modified nitrocellulose lacquer, or CAB-acrylic lacquer. While the distinctions within each finish type may seem minimal compared to the broader categories, they can still hold significance based on your specific needs and requirements. For instance, what sheen of lacquer should you pick for your kitchen cabinets.

By referring to the “Guide to Choosing a Finish”, you will gain further insights into the nuances of each finish type and how they can complement your woodworking project. Remember, even though the differences may be subtle, they can still make a meaningful impact on the final outcome.

So, take the time to explore the options within your chosen finish type, carefully weighing the variations to find the one that aligns best with your vision. With your newfound knowledge, you can confidently proceed with your woodworking project, knowing that you have made an informed decision about the finish that will enhance the beauty, protection, and longevity of your masterpiece.